复合袋热封不良的表现及其原因

发布于:2023/01/24

济南复合袋热封不良的表现及其原因基本有以下几种情况:

The performance and causes of poor heat sealing of Jinan composite bags are basically as follows:

1,热封强度不良。导致该现象主要的原因有粘结剂固化不彻底或热封温度太低。优化熟化工艺或适当提高封刀温度就可以改善这个问题。

1. The heat seal strength is poor. The main reason for this phenomenon is that the adhesive is not cured completely or the heat sealing temperature is too low. This problem can be improved by optimizing the curing process or properly increasing the sealing temperature.

2,热封面脱层、卷曲。导致该现象主要的原因是粘结剂未固化。调整固化时间或调节固化剂含量就可以改善这个问题。

2. The hot cover is delaminated and curled. The main reason for this phenomenon is that the adhesive is not cured. This problem can be improved by adjusting the curing time or the content of curing agent.

3,开口性不好/内层膜的开口性差。导致该现象的原因是开口剂太少,粘结料(改性剂)太多,薄膜表面有粘物或油腻。增加开口剂用量,调整改性剂用量,避免薄膜表面的二次污染等都可以改善这个问题。

3. Poor opening/poor opening of inner membrane. The reason for this phenomenon is that there are too few opening agents, too many binders (modifiers), and sticky or greasy substances on the film surface. This problem can be improved by increasing the amount of opening agent, adjusting the amount of modifier, and avoiding secondary pollution of the film surface.

此外对于常用的吹塑薄膜基材而言,其热封性除受树脂牌号影响外,还受挤出温度、吹胀比和牵引比、冷凝线、使用的再生料等因素的影响。

In addition, for the commonly used blown film substrate, its heat sealing is not only affected by the resin grade, but also by the extrusion temperature, blowing expansion ratio and traction ratio, condensation line, recycled materials used and other factors.

吹胀膜的热封性将随挤出温度的升高,氧化程度的升高而降低。

The heat sealing of the blown film will decrease with the increase of extrusion temperature and oxidation degree.

一定的吹胀比和牵引比有利于热封强度的提高,但由于薄膜吹胀和牵引实际上是使进入高弹态的分子产生定向,加快并促进其结晶化,结果在使薄膜的定向强度提高的同时,却使热封性即热封牢度减低了,因此,过大的吹胀比和牵引比是不合适的。

A certain blowing expansion ratio and traction ratio are beneficial to the improvement of the heat sealing strength, but because the blowing expansion and traction of the film actually make the molecules entering the high elastic state produce orientation, accelerate and promote their crystallization, the result is that while the directional strength of the film is improved, the heat sealing property, i.e. the heat sealing fastness, is reduced. Therefore, too large blowing expansion ratio and traction ratio are inappropriate.

The performance and reasons of poor heat sealing of composite bags have been solved for you, and more matters will come to our website http://www.sxsuliao.com Ask about it!

上一篇:自封袋在使用过程中要注意的6个事项

下一篇:印刷胶带脱胶的原因及解决办法

相关产品

-

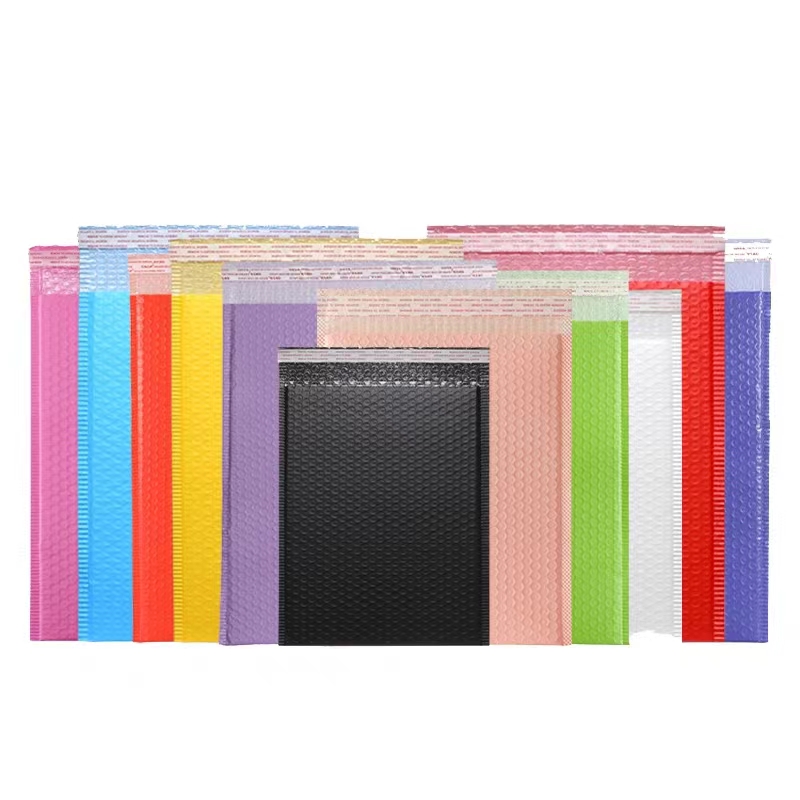

珠光膜气泡信封袋

-

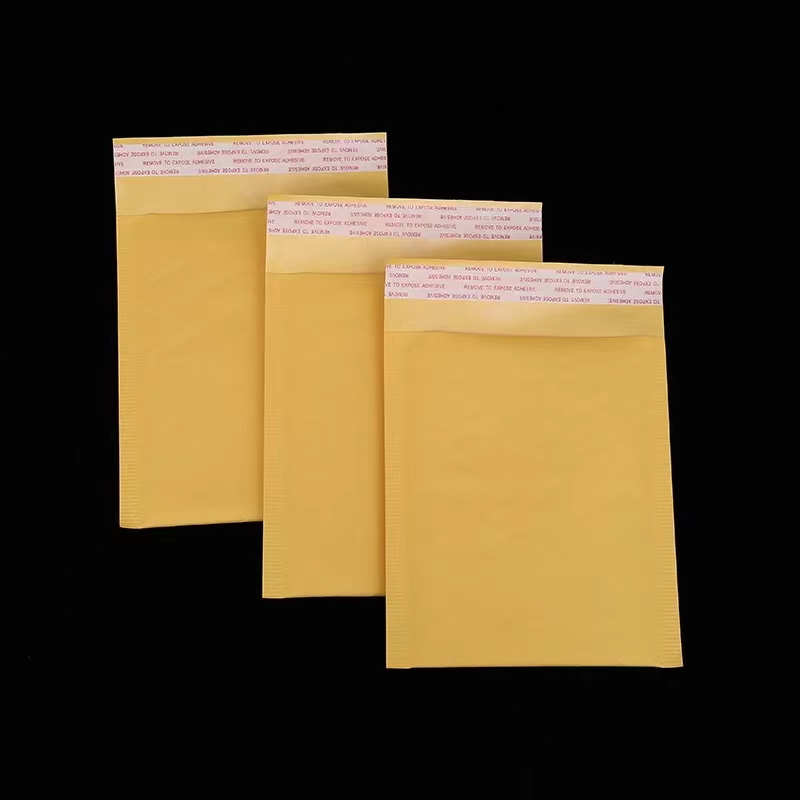

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

- 济南加厚快递袋 :快递袋都有哪些分类?

- 济南加厚快递袋有哪些种类?

- PE、PP、OPP等不同材质的自粘胶袋的区别

- 衣服包装袋选有孔防潮还是无孔防潮

- 食品真空包装设计及外真空包装材料介绍

- 食品真空包装设计及外真空包装材料原因

- 食品包装袋的袋型的选择

- PLA+PBAT包装袋的材质特点