复合袋生产期间出现复合气泡的原因

发布于:2022/12/23

复合中的气泡现象

Bubble phenomenon in recombination

1.薄膜润湿不良,应提高胶的浓度和涂布量,MST、KPT表面不易湿润,易产生气泡,特别在冬天。油墨上的气泡,用提高胶的用量的方法去除。

1. If the film is poorly wetted, the adhesive concentration and coating amount should be increased. The surface of MST and KPT is not easy to be wetted and is easy to produce bubbles, especially in winter. The bubbles on the ink can be removed by increasing the amount of glue.

2.油墨表面凹凸和起泡,应把复合膜的复合温度和复合压力提高。

2. If the ink surface is concave and convex and blistering, the composite temperature and pressure of the composite film should be increased.

3.油墨表面上的胶涂布量少,应增加复合辊的压贴时间及使用光滑辊筒、薄膜预热充分、降低复合速度、选择湿润性好的胶以及正确选用油墨。

3. The amount of glue coating on the ink surface is small, so it is necessary to increase the pressing time of the composite roller and use the smooth roller, fully preheat the film, reduce the composite speed, select the glue with good wettability and correctly select the ink.

4.薄膜中的添加剂(润滑剂、抗静电剂)被胶渗透,应选用分子量高、固化迅速的胶,提高胶浓度,提高烘箱温度充分使胶干燥,不使用超过3个月存放期的薄膜,因为电晕处理已丧失。

4. When the additives (lubricant, antistatic agent) in the film are penetrated by the glue, the glue with high molecular weight and rapid curing should be selected, the glue concentration should be increased, the oven temperature should be raised to fully dry the glue, and the film with a storage period of more than 3 months should not be used, because the corona treatment has been lost.

5.冬天里气温低,粘结剂对薄膜和油墨转移,润湿粘附效果不好,故操作场所保持一定温度。

5. In winter, the temperature is low, and the adhesive transfer to the film and ink, and the wetting and adhesion effect is not good, so the operating site should maintain a certain temperature.

6.干燥温度太高,发生胶的起泡或表皮结皮,内里不干,应调整胶干燥温度。

6. If the drying temperature is too high, blistering or skin scaling of the glue occurs, and the inside is not dry, the drying temperature of the glue should be adjusted.

7.

济南复合袋中的复合辊薄膜间夹带入空气,应提高复合辊温度,减小复合角(薄膜厚、硬时易产生气泡)。

7. Air is entrained between the film of the composite roll in Jinan composite bag. The temperature of the composite roll should be increased to reduce the composite angle (bubbles are easy to occur when the film is thick and hard).

8.由于薄膜阻隔性高,胶固化时产生的CO2气体,残留在复合膜中,未印刷处也有气泡,应提高固化剂量,使胶在干燥中固化。

8. Due to the high barrier property of the film, the CO2 gas generated during the curing of the adhesive remains in the composite film and there are bubbles at the unprinted part. The curing dose should be increased to make the adhesive solidify in the dry.

9.胶中的脂酸乙酯是油墨粘结料的良好溶剂,胶溶渗了油墨,只在油墨上有气泡,应避免水分渗入胶中及提高胶干燥温度,减少对油墨的溶渗。

9. The ethyl fatty acid in the glue is a good solvent for the ink binder. The glue dissolves the ink and only bubbles on the ink. It is necessary to avoid water infiltration into the glue and increase the drying temperature of the glue to reduce the penetration of the ink.

The causes of compound bubbles during the production of composite bags and the countermeasures are as above. I hope to give you good help. Whether it is production or use, we should do a good job in understanding matters and pay attention to us http://www.sxsuliao.com Tell you more!

上一篇:自封袋的弹性强度以及相应分类

下一篇:企业在选择包装印刷胶带时应了解什么?

相关产品

-

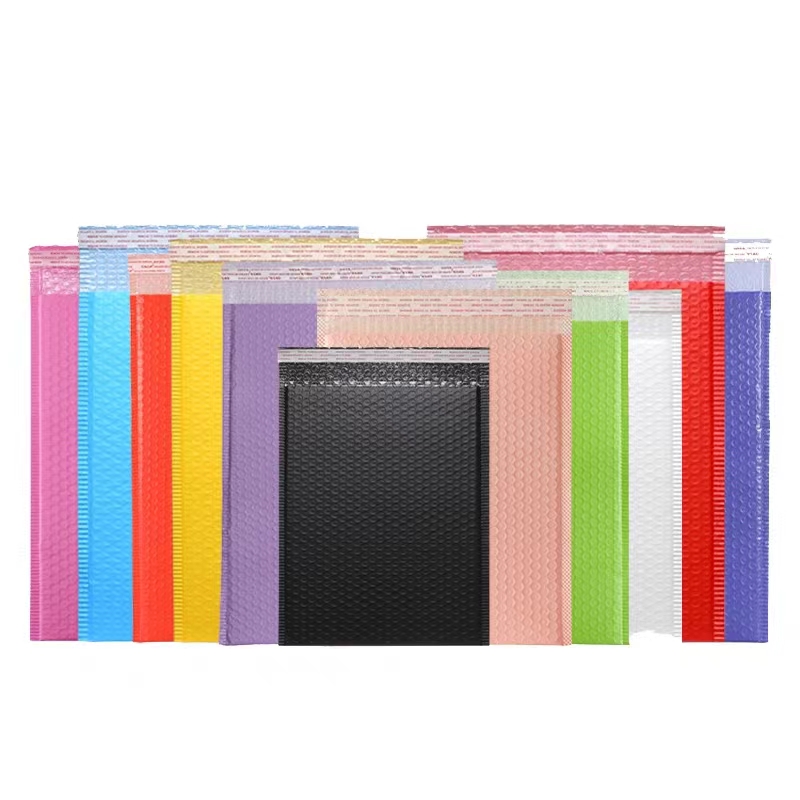

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

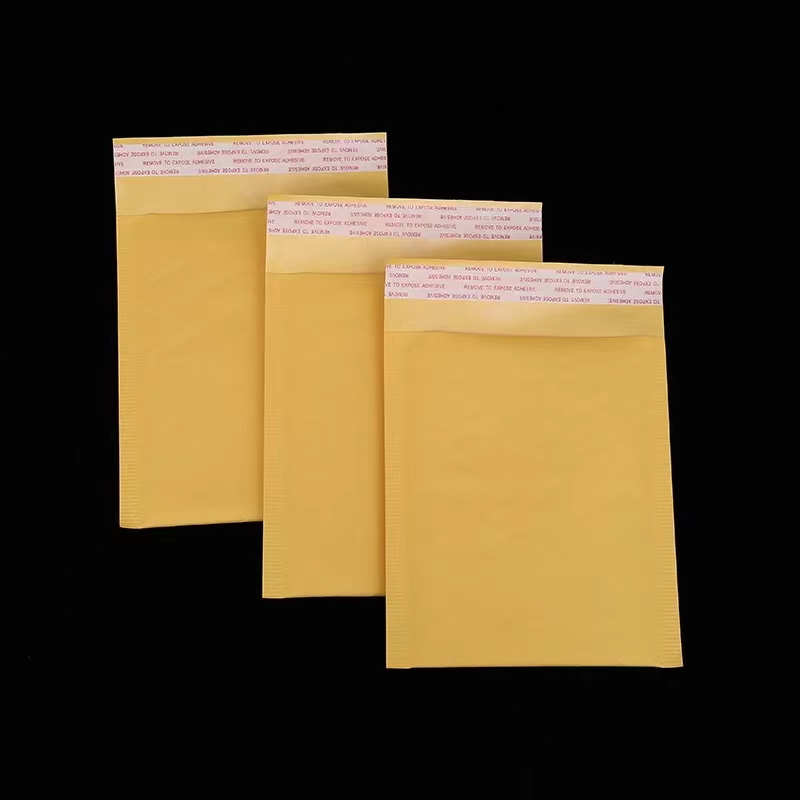

- 牛皮纸复合气泡袋知识

- 快递气泡包装袋为什么比较好用?

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响