阀口袋厂家如何检测复合袋?

发布于:2022/03/29

阀口袋厂家如何检测复合袋?

How do valve pocket manufacturers detect composite bags?

外观视觉检查包含对复合袋平整度、清晰度的检查等项目。主要用于检测复合袋外表有无明显的擦伤和针孔,封口处是否污染等。

Visual appearance inspection includes the inspection of flatness and clarity of composite bags. It is mainly used to detect whether there are obvious scratches and pinholes on the surface of the composite bag, and whether the sealing part is polluted.

(1)将复合袋放置手中,对准40W日光灯悄悄晃动,经过复合袋外表的反射光,即可清楚地发现复合袋外表是否有划伤或痕迹,业界常常称为“袋面拉丝”。如果拉丝严峻则应依据实际状况,找到毛病地点,将影响降低点,保证产品质量。我们经过调查发现的拉丝现象多半是由制袋机牵引导辊不洁净形成的,因而一定要保证导辊洁净。此外,导辊不滚动相同会使复合袋发生拉丝毛病。导辊不滚动的原因多由轴承缺油形成,因而保持良好的光滑是轴承滚动的根本条件。

(1) Place the composite bag in your hand, aim at the 40W fluorescent lamp and shake it quietly. After the reflected light on the surface of the composite bag, you can clearly find whether there are scratches or traces on the surface of the composite bag. It is often called "bag surface wire drawing" in the industry. If the wire drawing is severe, find the fault location according to the actual situation, reduce the impact to a low point and ensure the product quality. After investigation, we found that most of the wire drawing phenomenon is formed by the unclean traction guide roller of the bag making machine, so we must ensure that the guide roller is clean. In addition, the different rolling of the guide roller will cause the wire drawing problem of the composite bag. The reason why the guide roller does not roll is mostly caused by the lack of oil in the bearing, so maintaining good smoothness is the fundamental condition for bearing rolling.

(2)复合袋平整度的检查。具体方法是:抽取数张制品袋样张进行“空对地”投落,让其自然着地(着地点要洁净),调查复合袋着地后的状况。如果复合袋着地时发作曲折,向外翘或向内拱,则阐明复合袋的平整度差,反之则阐明平整度保持良好。形成平整度差的原因一般有以下几点:制袋温度偏高,已破坏复合袋内层的应力挺度;结构组成不合理;资料自身厚薄不平等。留意,当PET/PE和BOPP/PET/PE结构的复合资料总厚度不超过80μm时,易发作平整度变差的现象。

(2) Inspection of flatness of composite bag. The specific method is: take several sample sheets of product bags for "air to ground" dropping, let them land naturally (the landing place should be clean), and investigate the condition of composite bags after landing. If the composite bag is tortuous, warped outward or arched inward when landing, it indicates that the flatness of the composite bag is poor, otherwise, it indicates that the flatness remains good. The reasons for poor flatness are generally as follows: the bag making temperature is too high, which has damaged the stress stiffness of the inner layer of the composite bag; Unreasonable structural composition; The thickness of data itself is unequal. Note that when the total thickness of composite materials of PET / PE and BOPP / PET / PE structures does not exceed 80 μ M, the phenomenon of poor flatness is easy to occur.

(3)外观视觉检查还包含清晰度的检查。有些产品因为大面积无图画,清晰度显得尤为重要。清晰度的检测方法是:抽取一张制品袋,透过室内直接光源调查,如果空白处有“麻点”、“环状物”、“雾状”等现象,则阐明清晰度差,反之标明清晰度保持良好。

(3) Visual appearance inspection also includes clarity inspection. In some products, clarity is particularly important because there are no pictures in a large area. The detection method of sharpness is: take a piece of product bag and investigate through the indoor direct light source. If there are "pits", "rings", "fog" and other phenomena in the blank, clarify that the sharpness is poor, otherwise indicate that the sharpness remains good.

形成清晰度差的原因是各个方面的,例如:在进行复合时,因为复合胶液自身色泽偏黄或偏红,转移复合袋上会发生相应的偏色,影响其清晰度;如果资料自身清晰度差,有“雾状”,也将影响其清晰度,因而在资料进仓时应该严把质量关,做到不合格质料不进仓。此外,不一样的复合原资料清晰度也不一样,如流延CPP的清晰度比吹塑共挤CPP的清晰度高得多。

The reasons for the poor definition are various. For example, when compounding, because the color of the composite glue is yellow or red, the corresponding color deviation will occur when transferred to the composite bag, affecting its definition; If the clarity of the data itself is poor and "foggy", it will also affect its clarity. Therefore, the quality of the data should be strictly controlled when entering the warehouse, so that the unqualified materials will not enter the warehouse. In addition, the clarity of different composite raw materials is also different. For example, the clarity of tape casting CPP is much higher than that of blow molding co extrusion CPP.

The above is the detailed introduction of Jinan composite bag. I hope it will be helpful to you If you have any questions, please contact us We will provide you with professional service http://www.sxsuliao.com

上一篇:气泡膜的原理和应用

下一篇:泡泡袋都有哪些分类?

相关产品

-

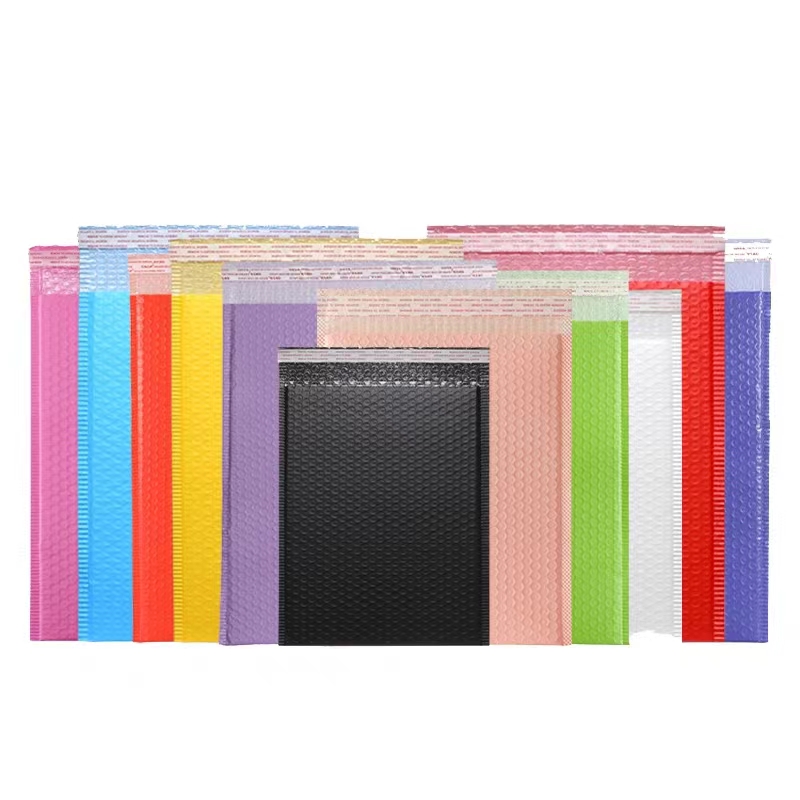

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

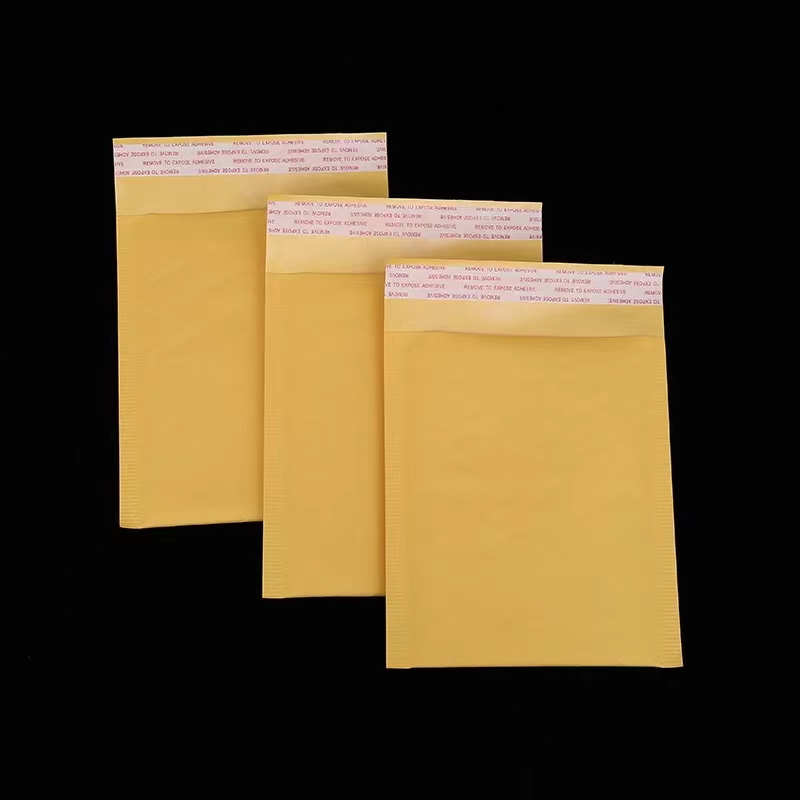

- 牛皮纸复合气泡袋知识

- 快递气泡包装袋为什么比较好用?

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响