常见检测自封袋密封性方法

发布于:2022/03/15

自封袋虽然非常方便,但是密封性能也很重要。在设计自封袋时,需要充分考虑每层材料的性能和厚度,以获得足够的阻隔性能。检测自封袋密封性能的常用方法有三种:

Although the self sealing bag is very convenient, the sealing performance is also very important. When designing self sealing bags, the performance and thickness of each layer of materials need to be fully considered to obtain sufficient barrier performance. There are three common methods to test the sealing performance of self sealing bags:

1.无水浸泡法。

1. Anhydrous immersion method.

自封袋通常适用于外层材料性能在水的作用下在测试过程中会明显下降的包装,如外层为纸质材料的包装。

Self sealing bags are usually suitable for packaging where the performance of the outer material will decrease significantly under the action of water, such as packaging with paper material.

用试液(如与滤纸有明显色差的有色水溶液)填充样品,密封后将样品放在滤纸上,观察试液从样品内到外的渗漏情况。应该从两方面来衡量。也可以放在真空室中,在负压下测试。

Fill the sample with test solution (such as colored aqueous solution with obvious color difference with the filter paper), place the sample on the filter paper after sealing, and observe the leakage of test solution from inside to outside of the sample. It should be measured from two aspects. It can also be placed in a vacuum chamber and tested under negative pressure.

二、真空观察法。

2、 Vacuum observation method.

自封袋的适用材料同上。通过抽真空,产生样品内部和外部的压力差,观察膨胀和释放真空后样品形状的恢复,判断样品的密封性能。

The applicable material of self sealing bag is the same as above. By vacuumizing, the pressure difference inside and outside the sample is generated, and the recovery of sample shape after expansion and vacuum release is observed to judge the sealing performance of the sample.

第三,城市压在水里。

Third, the city is under pressure.

自封袋通常适用于外层材料性能在水的作用下在试验过程中不会明显下降的包装,如外层采用塑料薄膜的包装。通过对真空室抽真空,产生浸入水中的样品内部和外部的压力差,观察样品中的气体逸出或水分渗入,测量样品的密封性能。测量密封性能常用的手段是具有真实速率的测试装置。

Self sealing bags are usually suitable for packaging in which the performance of the outer material will not decrease significantly under the action of water, such as packaging with plastic film. By vacuumizing the vacuum chamber, the pressure difference between the inside and outside of the sample immersed in water is generated, the gas escape or water infiltration in the sample is observed, and the sealing performance of the sample is measured. The common means to measure the sealing performance is the test device with real rate.

目前市场上很多商品都存在产品质量问题,总有穷店为了更好地实现目标而铤而走险。因此,我们在购买自密封袋时要特别注意,自密封袋因其方便易用而被广泛应用于食品等各个领域。很多人会问如何辨别自封袋是否有害。

At present, many goods in the market have product quality problems. There are always poor stores who take risks in order to better achieve their goals. Therefore, we should pay special attention when purchasing self sealing bags. Self sealing bags are widely used in various fields such as food because of their convenience and ease of use. Many people will ask how to identify whether self sealing bags are harmful.

1.用双眼看。

1. Look with both eyes.

包装袋为白色、全透明或微全透明,材质匀称。有害密封包装袋为彩色或白色,但透明度和浊度较弱。塑料表层拉伸不均匀,含有小颗粒。

The non-toxic packaging bag is white, fully transparent or slightly fully transparent, and the material is symmetrical. The harmful sealed packaging bag is colored or white, but the transparency and turbidity are weak. The plastic surface layer is stretched unevenly and contains small particles.

2.听听你的耳朵。

2. Listen to your ears.

当用力摇晃包装袋时,会发出清晰的声音,表明是包装袋。而低噪音是有害的包装袋。

When shaking the bag, it will make a clear sound, indicating that it is a non-toxic bag. And low noise is harmful to the packaging bag.

The above is the detailed introduction of Jinan self sealing bag. I hope it will be helpful to you If you have any questions, you are welcome to contact us We will provide you with professional service http://www.sxsuliao.com

上一篇:印刷封箱胶带不沾的原因是什么?

下一篇:气泡膜的原理和应用

相关产品

-

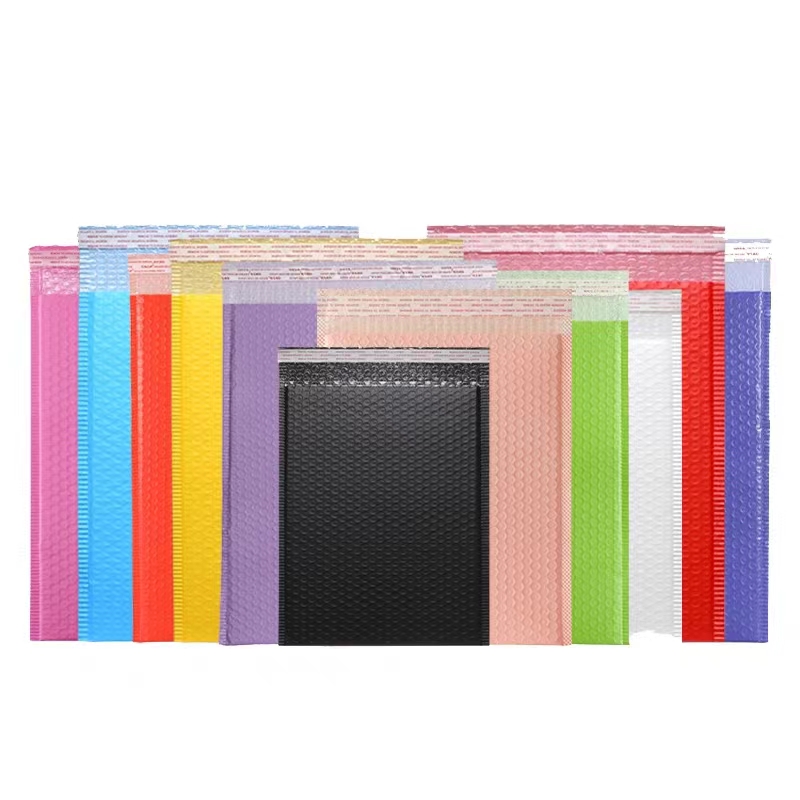

珠光膜气泡信封袋

-

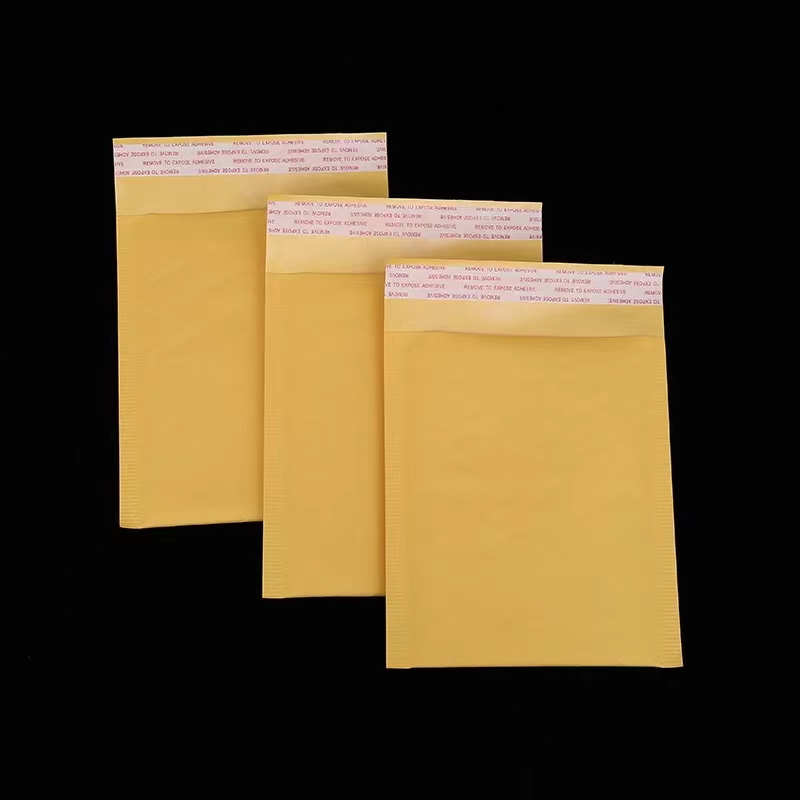

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

- 济南加厚快递袋 :快递袋都有哪些分类?

- 济南加厚快递袋有哪些种类?

- PE、PP、OPP等不同材质的自粘胶袋的区别

- 衣服包装袋选有孔防潮还是无孔防潮

- 食品真空包装设计及外真空包装材料介绍

- 食品真空包装设计及外真空包装材料原因

- 食品包装袋的袋型的选择

- PLA+PBAT包装袋的材质特点