自封袋的盲孔是如何形成的?

发布于:2022/02/26

有些塑料自封袋品成型后得到一个盲孔,然后钻通,这种方法适用于细而深的孔,可防止在成型时型芯变型。塑制品成型后无孔,以后二次加工出孔。后两种刀法只限于对少数易于切削的材料尼龙等。同时因为要二次加工。生产效率低,对精细孔的质量也难以保证,所以用得很少。本节主要介绍成型时直接生成的孔的设计原理及加工方法。

Some plastic self sealing bags get a blind hole after forming and then drill through. This method is suitable for thin and deep holes to prevent core deformation during forming. Plastic products have no holes after forming, and then the holes will be processed again. The latter two knife methods are limited to a few easy cutting materials, such as nylon. At the same time, because of secondary processing. The production efficiency is low, and it is difficult to guarantee the quality of fine holes, so it is rarely used. This section mainly introduces the design principle and processing method of the hole directly generated during forming.

对在成型时直接生成的孔,无论伺种类型,均应设置在不易削弱制品强度的部位,且孔的形状应力求不使模具制造工艺复杂化。是在成型的制品残留熔接痕和削弱强度的重要因素。周围设一个凸边来加强。同时,孔与孔的间距及几到制品边缘的距离也要适当。所示的尺寸关系确定,当两个孔不一“样大小时,按小7L取值;热塑性塑料自封袋的注塑制品按表2—7中数值的75%取恒。不同类型的孔的深因成型方法的不同而不同。通孔注塑制品L的通扎用得很多,成型通孔用的型芯一般有以门L种安装办法。

For the holes directly generated during forming, regardless of the type, they should be set at the parts that are not easy to weaken the strength of the products, and the shape of the holes should strive not to complicate the mold manufacturing process. It is an important factor for residual weld lines and weakening strength of formed products. A convex edge is set around to strengthen. At the same time, the spacing between holes and the distance from several to the edge of the product should also be appropriate. According to the dimensional relationship shown in, when the two holes are different in size, the value shall be taken as 7L; the injection molded products of thermoplastic self sealing bags shall be taken as 75% of the value in table 2-7. The depth of different types of holes varies with different molding methods. The through-hole injection molded products L are used a lot, and the core for forming through-hole generally has l installation methods.

内一端固定的型芯来成型,且易生成飞边,当型芯较细时易弯曲。这种固定型芯的方法不能成型深孔。由两个两端固定的则芯来成型,由于将一个型芯设计得比另一个大o.5—1mm左右,保证孔的同心度,不于引起安装和使用土的困难,而且增加了型芯的稳定性,孔的精度低。由一端固定,一端导向支撑的型芯来成型,这样型芯有较好的强度和刚度,又能保证同心度,但导向部分易因导向误差磨损而产生圆弧溢料。以上无论采用何种固定方法,孔的深均不能太大,公则型芯会弯曲。通常九探随塑料流动性的4(同而不同,流动性好的塑料自封袋的7L的深可以达到10倍孔径,流动性中等的不能超过7倍孔径,而流动性差的塑料制品的孔深小于4倍7L径;否则只能采取机械加工的力法获得。

The inner end is formed by a fixed core, and it is easy to generate flash. When the core is thin, it is easy to bend. This method of fixing the core cannot form deep holes. It is formed by two cores fixed at both ends. Because one core is designed to be about 0.5-1mm larger than the other, the concentricity of the hole is guaranteed, which will not cause difficulties in installation and use of soil, and increase the stability of the core, and the accuracy of the hole is low. It is formed by the core with one end fixed and one end guided and supported, so that the core has better strength and stiffness and can ensure concentricity, but the guide part is easy to produce arc overflow due to the wear of guide error. No matter what fixing method is adopted, the hole depth should not be too large, and the core will be bent. Generally, the depth of 7L of plastic self sealing bag with good fluidity can reach 10 times the aperture, and that of plastic products with medium fluidity can not exceed 7 times the aperture, while that of plastic products with poor fluidity is less than 4 times the 7L diameter; otherwise, it can only be obtained by mechanical processing.

上一篇:为什么气泡袋的单价相差这么大

下一篇:复合袋的设计原则有哪些?

相关产品

-

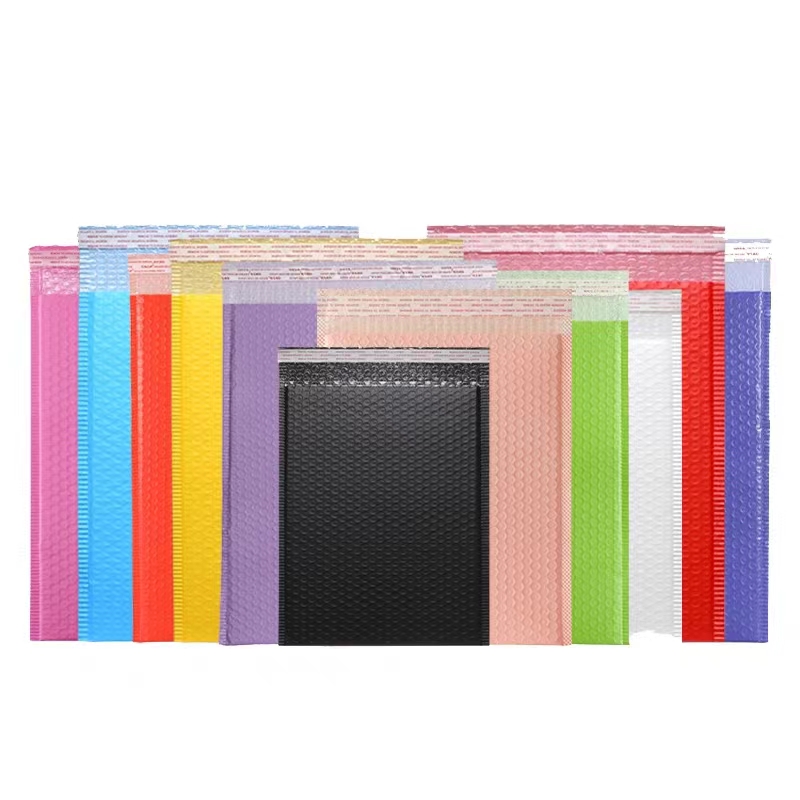

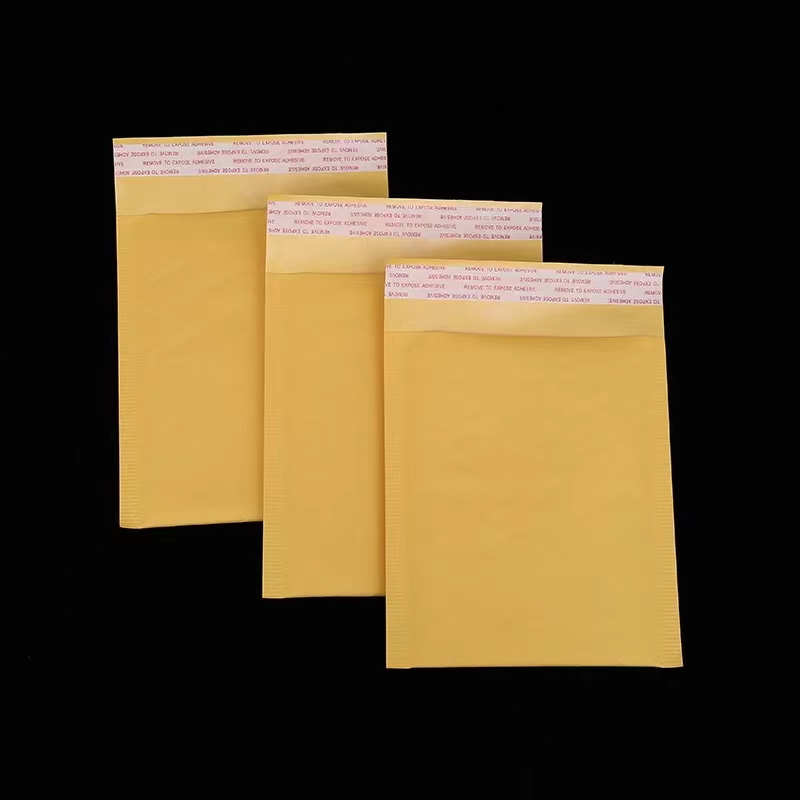

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

- 济南加厚快递袋 :快递袋都有哪些分类?

- 济南加厚快递袋有哪些种类?

- PE、PP、OPP等不同材质的自粘胶袋的区别

- 衣服包装袋选有孔防潮还是无孔防潮

- 食品真空包装设计及外真空包装材料介绍

- 食品真空包装设计及外真空包装材料原因

- 食品包装袋的袋型的选择

- PLA+PBAT包装袋的材质特点