软包装复合袋两个检测方法

发布于:2021/04/22

软包装复合袋具有杰出的阻隔性、热封性、防潮性,且耐酸、耐碱、耐磨,因而被广泛用于食物的外包装。随着大家对软包装复合袋质量请求的日益进步,包装企业对软包装复合袋的质量查看也越来越注重。今天这篇文章我们就来探讨一下应该如何检测软包装复合袋是否符合要求。

Flexible packaging composite bag has outstanding barrier, heat sealing, moisture resistance, acid resistance, alkali resistance, wear resistance, so it is widely used in food packaging. With the increasing progress of the quality requirements of flexible packaging composite bags, packaging enterprises pay more and more attention to the quality inspection of flexible packaging composite bags. Today, in this article, we will discuss how to detect whether the flexible packaging composite bag meets the requirements.

1.外观视觉查看:外观视觉查看包含对复合袋平整度、透明度的查看等项目。主要用于查看复合袋外表有无显着的擦伤和针孔,封口处有无污染等

1. Appearance visual inspection: the appearance visual inspection includes the inspection of the flatness and transparency of the composite bag. It is mainly used to check whether there are obvious abrasions and pinholes on the surface of the composite bag, and whether there is pollution at the seal

2.封口密合性的查看

2. Check the sealing tightness

封口处一些纤细的小缝,在视觉查看上稍有忽略就会为日后食物的渗漏埋下危险,因而对复合袋进行封口密合性查看很有必要。常用的办法为:将一种加有染料的外表活性剂喷于封口内,调查其透过与否,假如染料色泽透过封口处,则阐明密封功能欠好,相反则阐明符合密封质量请求。

Some tiny seams at the sealing place, if neglected in the visual inspection, will lay a danger for the future food leakage, so it is necessary to check the sealing tightness of the composite bag. The common method is: spray a kind of surface active agent with dye into the seal to investigate whether it passes through. If the dye color passes through the seal, it indicates that the sealing function is not good. On the contrary, it indicates that it meets the sealing quality requirements.

在实际工作中,咱们常用一把长20cm、宽5cm、厚0.8mm的光滑、无毛刺的小铁尺对其封口密合处用力推顶。假如轻轻一顶便有掉落、穿孔等景象,则阐明密封功能差;若封口处仍然坚持应有的封合尺度,则阐明密封功能杰出。

In practical work, we usually use a smooth, burr free small iron ruler with a length of 20cm, a width of 5cm and a thickness of 0.8mm to push the sealing joint. If there are falling, perforation, etc. on one top, it indicates that the sealing function is poor; if the sealing part still adheres to the proper sealing scale, it indicates that the sealing function is excellent.

导致密封功能差的因素有:封刀压力不行或不均,这种状况只要调理封刀弹簧压力即可处理;温度偏低也会使复合袋封口处密合性变差。咱们注意到,当复合资料总厚度超越80μm时,在制袋加工时易发作密合性变差的疑问,尤其是BOPP/OPP的构造易发作。要想确保商品密合性优良,一定有均匀平稳的密封压力及合适的温度。

The reasons for the poor sealing function are: the pressure of the sealing knife is not good or uneven, which can be treated by adjusting the spring pressure of the sealing knife; the low temperature will also make the sealing of the composite bag worse. We notice that when the total thickness of the composite material exceeds 80 μ m, it is easy to have the problem of poor tightness, especially the structure of BOPP / opp. In order to ensure good tightness, there must be uniform and stable sealing pressure and appropriate temperature.

上一篇:复合包装胶袋的离层是什么

下一篇:印刷胶带残留物如何去除呢?

相关产品

-

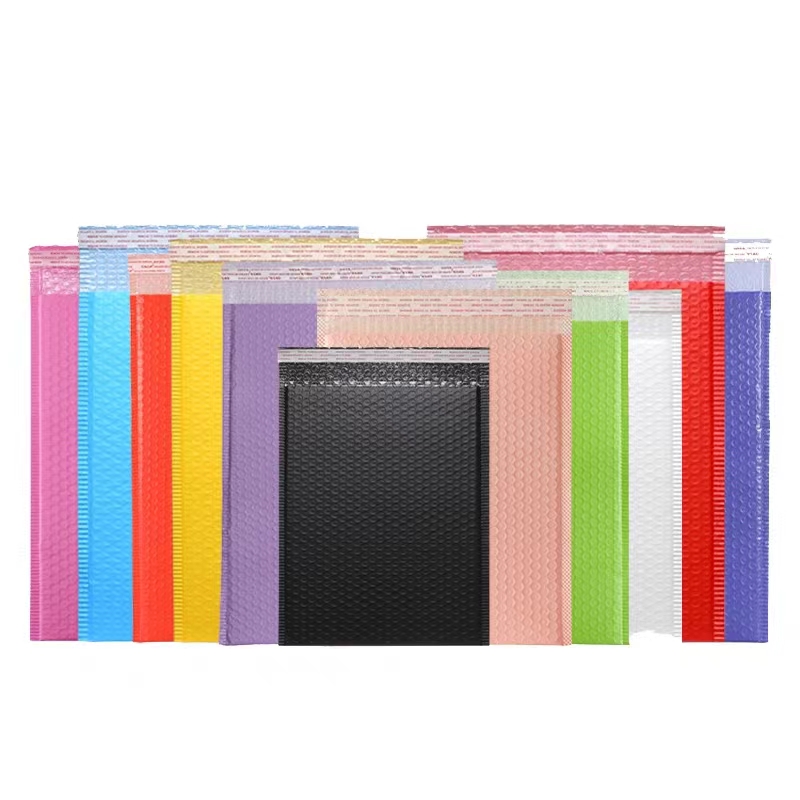

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

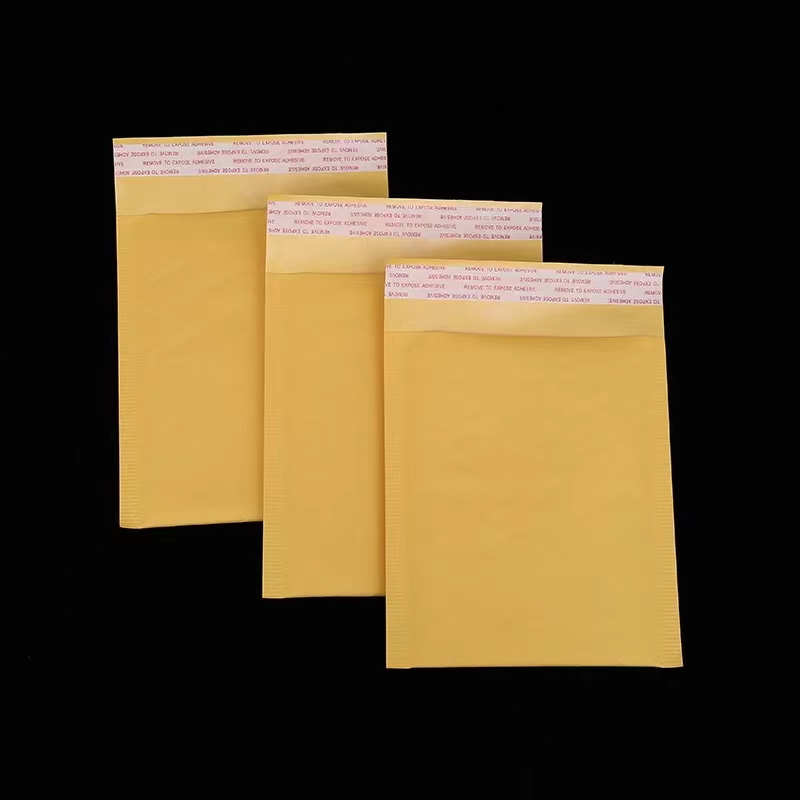

- 牛皮纸复合气泡袋知识

- 快递气泡包装袋为什么比较好用?

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响