气泡袋的生产工艺的重要性!

发布于:2020/10/12

气泡袋的使用好坏可以看出来气泡袋的生产工艺是怎样的,因此我们也可以看出来质量好的气泡袋生产工艺是非常不错的,因此了解一下气泡袋的生产工艺是非常重要的,小编给大家做了一些有方面的整理,在下文给大家做个分享。

The use of bubble bag can see how the production process of bubble bag is. Therefore, we can also see that the production process of bubble bag with good quality is very good. Therefore, it is very important to understand the production process of bubble bag. I made some arrangement for you, and I would like to share it with you.

济南气泡袋

Jinan bubble bag

1:气泡袋的模具制作及加工:根据要求或样品规格,制作好吸塑模具,一般条件下,都是利用石膏制作吸塑包装模具,但也有用木雕及金属雕刻的产品作模具,石膏模具制作好后,先让其自然干燥完全或是烘干,然后根据产品表面凸凹具体情况,用1-2毫米钻花在不影响产品包装模样的低凹处钻许多小孔,如果是包装盒之类产品,还得在四周边上钻一些小孔,以便吸塑生产时,能将空气抽出,模具钻好孔后,还得将石膏模具进行加硬处理,加硬处理方法是用浓明矾饱和液浸泡后晾干。

1: Bubble bag mold making and processing: according to the requirements or sample specifications, first make a good blister mold, under general conditions, the use of gypsum to make blister packaging mold, but also use wood carving and metal carving products as the mold, after the gypsum mold is made, first let it dry completely or dry, and then according to the specific situation of the product surface convex concave, use 1-2 mm drill flower Many small holes should be drilled in the concave places that do not affect the product packaging pattern. If it is a packaging box or other products, some small holes should be drilled around the four sides so that the air can be drawn out during the blister production. After the mold is drilled, the gypsum mold must be hardened. The hardening treatment method is to soak in concentrated alum saturated solution and dry it in the air.

2:模具处理干燥完全后,将模具装入真空室上层铁板上,然后根据模具大小,将塑料片载成适用规格尺寸,然后将此片材放入加热木柜内,使其完全固定好,再将木柜连同塑料片材置恒温炉上进行软化处理。

2: After the mold is completely dried, the mold is put into the upper iron plate of the vacuum chamber, and then the plastic sheet is loaded into the applicable size according to the size of the mold, and then the sheet is put into the heating wood cabinet to make it completely fixed, and then the wood cabinet and the plastic sheet are placed on the constant temperature furnace for softening treatment.

3:将软化处理好的塑料片连同木柜,置于真空室中,开动吸气开关,将真空室内空气吸抽干净,待塑料片冷却后,即得到与气泡袋模具相同的凹型包装或工艺模具。

3: Put the softened plastic sheet together with the wooden cabinet in the vacuum chamber. Turn on the suction switch to suck the air in the vacuum chamber. After the plastic sheet is cooled, the concave packaging or process mould which is the same as the bubble bag mold can be obtained.

4:吸塑包装整理;将生产出来的产品进行修边整理即为成品产品,再经包装后即可出售。

4: Blister packing and finishing; trimming and finishing the products are finished products, which can be sold after packaging.

这是气泡袋的生产工艺了!经过这样处理的气泡袋使用起来是非常不错的,而且我们也可以了解到其中的优势,如果有消费者需要购买OPP袋,气泡袋这些产品的话,可以直接电话联系我们的哦!

This is the production process of bubble bag! After such treatment, the bubble bag is very good to use, and we can also understand its advantages. If consumers need to buy OPP Bags, bubble bags and other products, they can contact us directly by telephone!

关键词:

济南气泡袋

相关产品

-

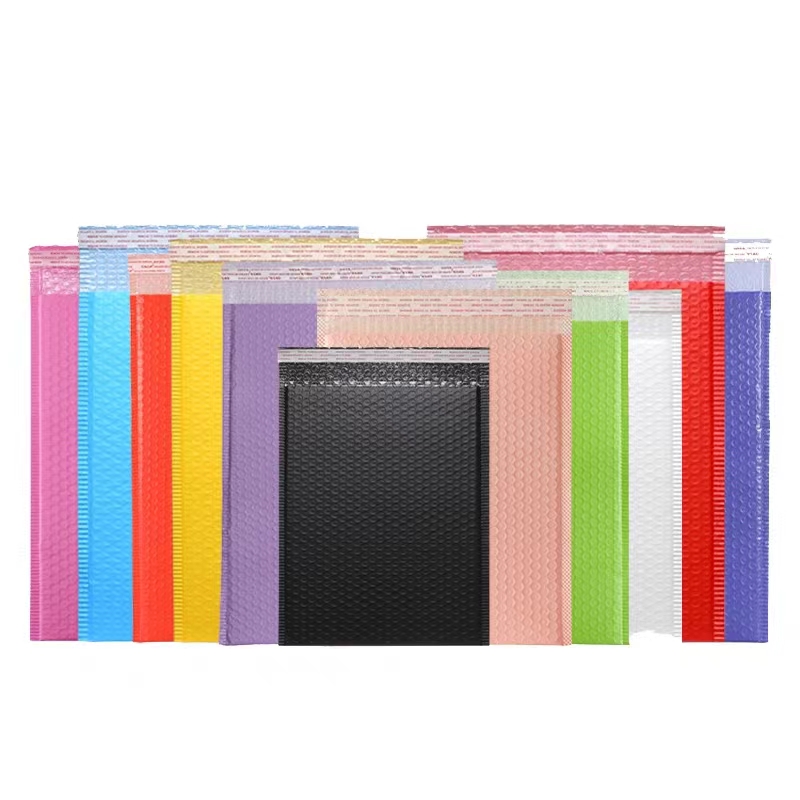

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

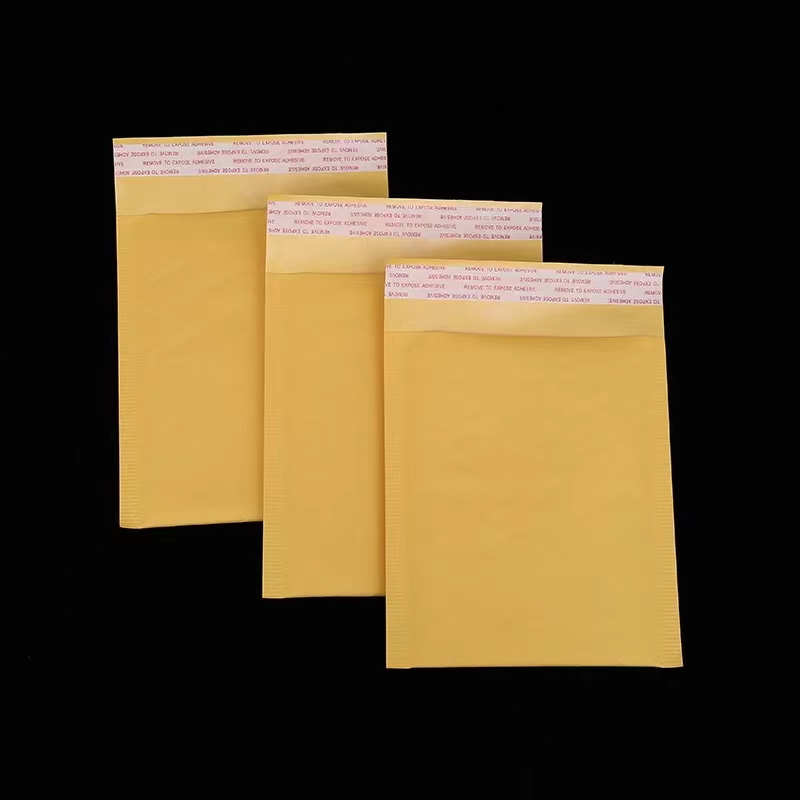

- 牛皮纸复合气泡袋知识

- 快递气泡包装袋为什么比较好用?

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响