影响复合袋热封强度和焊缝处分层的因素有哪些?

发布于:2020/07/09

添加剂主要是指使用润滑剂在聚乙烯薄膜的生产过程,特别是外部润滑剂,它们中的大多数都是一些低熔点蜡,容易给薄的外表,实践证明,当聚乙烯薄膜厚度超过60,添加剂给现场将大大增加。将平等的外表下产品,随着膜厚度的增加,其内部添加剂测量也增加,所以攻击的可能性也会增加,分出的添加剂对复合膜阻挡层,大大地削弱了复合强度,尤其是在封边轴承简单的开口,离层,一些制造商生产的真空袋经常遇到这样的问题。

Additives mainly refer to the use of lubricants in the production process of polyethylene film, especially external lubricants. Most of them are low melting point waxes, which are easy to give thin appearance. Practice has proved that when the thickness of polyethylene film exceeds 60, the additives will greatly increase to the site. With the increase of film thickness, the measurement of internal additives will increase, so the possibility of attack will also increase. The separated additives will greatly weaken the composite strength of composite film barrier layer, especially in the simple opening and separation layer of edge sealing bearing. Some manufacturers often encounter such problems in vacuum bags.

解决方案:

Solution:

一、在复合前仔细检查外观张力,有必要达到要求,有必要能够进行edm从头处理,因为蜡在edm下可以蒸发,有高温效果。

I. carefully check the appearance tension before compounding, it is necessary to meet the requirements, it is necessary to be able to carry out EDM head treatment, because wax can evaporate under EDM, with high temperature effect.

选择合适的胶黏剂,即要加强胶的夹杂物对添加剂的分离,使其影响到强度。

To select the proper adhesive, it is necessary to strengthen the separation of the inclusion of the adhesive from the additive, so that it can affect the minimum strength.

固化控制与镀铝膜不一样,应尽量在低温条件下固化,以防止高温增加分离。粘接剂的影响,粘接剂的选择更终由含量决定,不同的含量,不同的基材,不同的使用应根据实际情况尝试选择组合粘接剂,否则同样影响热封强度。

The curing control is different from that of aluminizing film. It should be cured at low temperature to prevent separation at high temperature. The effect of adhesive, the choice of adhesive is ultimately determined by the content, different content, different substrate, different use should be based on the actual situation to try to choose a combination of adhesive, otherwise it also affects the heat sealing strength.

例如:当在包上的冲击(液体或粉末),由于重内容(下降),达到密封的强度有较高的要求,体育添加必要的厚度考虑滑剂分离问题,提倡使用高盟公司YH501SL辅助胶粘剂和密封强度和剥离强度将大大进步。如果有铝箔胶,我们要求接触强度很好。yh2000铝箔胶完全符合质量要求。yh2000年以后,铝箔胶粘剂不仅具有较高的初粘性,而且还含有“亲铝基团”,可以提高胶粘剂与铝箔的接触强度。高蒙生产的YH3150和YH3166也属于这类胶,可用于煮袋和覆膜。如果复合涂层结构选用YH501S, YH501SL镀铝胶将对热封强度和密封强度有很大的提高。

For example: when the impact on the package (liquid or powder), due to the heavy content (drop), there is a higher requirement to reach the sealing strength, sports add the necessary thickness to consider the problem of the separation of the sliding agent, and promote the use of yh501sl auxiliary adhesive of GAOMENG company and the sealing strength and peeling strength will be greatly improved. If there is aluminum foil adhesive, we require good contact strength. Yh2000 aluminum foil adhesive completely meets the quality requirements. After yh2000, aluminum foil adhesive not only has high initial viscosity, but also contains "aluminophilic group", which can improve the contact strength between adhesive and aluminum foil. Yh3150 and yh3166 produced by GAOMENG also belong to this kind of glue, which can be used for bag boiling and film covering. If yh501s is selected as the composite coating structure, yh501sl aluminum coating adhesive will greatly improve the heat sealing strength and sealing strength.

综上所述,影响复合袋热封强度和复合袋焊缝处分层的因素还有很多,需要在生产过程中进行很好的总结。

To sum up, there are many factors that affect the heat sealing strength of composite bags and the separation of weld layers of composite bags, which need to be summarized in the production process.

上一篇:气泡袋主要有哪些重要的作用?

下一篇:影响复合袋热封强度和焊缝处分层的因素有哪些?

相关产品

-

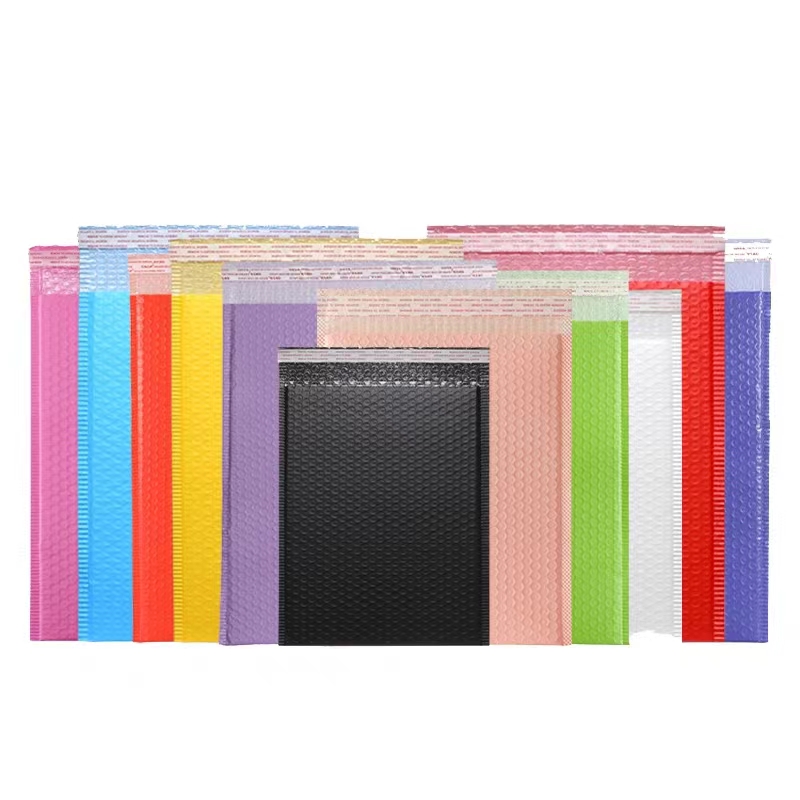

珠光膜气泡信封袋

-

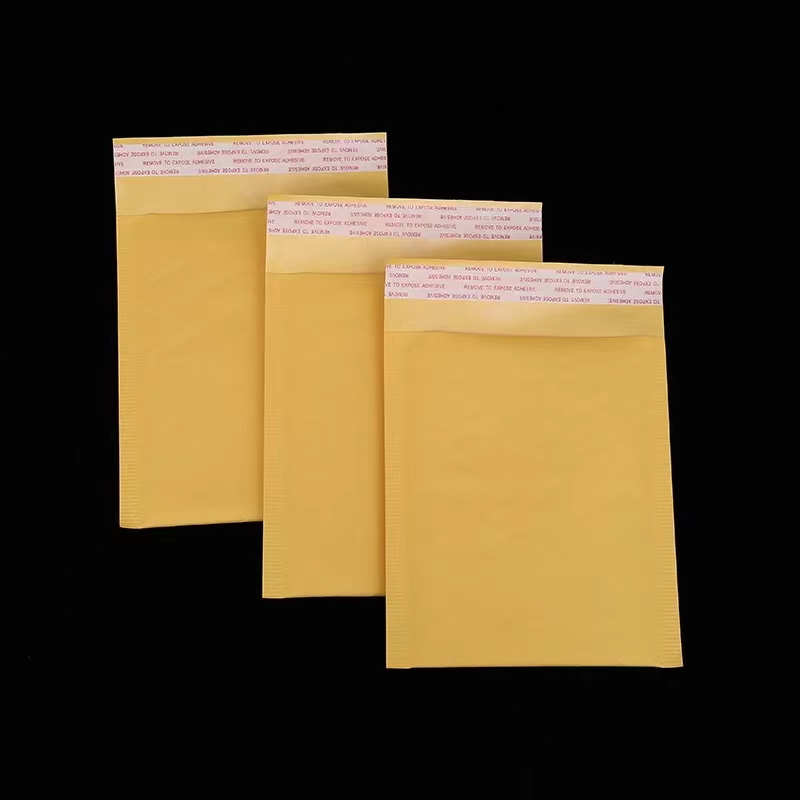

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响

- 选购视频塑料包装袋要注意什么?

- OPP自粘袋的材料制作介绍