济南复合袋的工艺特点是什么?

发布于:2020/07/02

复合袋是由聚酯、尼龙、铝箔和特种聚烯烃等薄膜用胶粘剂通过干式复合工艺制成复合膜,然后经熟化、分切、制成蒸煮袋。复合袋在包装食物后,还要经121~135 ℃、30~40 min的高温处理。不但用于制袋的薄膜要耐高温,而且用于粘接薄膜的胶粘剂也要耐高温,否则蒸煮后容易发生薄膜间粘接强度下降、脱层等不好现象。

The composite bag is made of polyester, nylon, aluminum foil and special polyolefin films by dry laminating process with adhesive, and then cooked, cut and made into cooking bag. After packaging food, the composite bag should be sterilized at 121-135 ℃ for 30-40 min. Not only the film used for bag making should be resistant to high temperature, but also the adhesive used for bonding the film should also be resistant to high temperature. Otherwise, the adhesion strength between the films will be reduced and delamination will occur after cooking.

现在市场上首要用于蒸煮袋复合用的胶粘剂首要是国外进口产品。由化工研究院研制出了一种耐135 ℃高温的蒸煮袋用胶粘剂,经数次上机复合试验,其耐蒸煮性、耐内容物性、卫生性均满意国内厂家的要求。

At present, the most important adhesive used for cooking bag composite is imported products. A 135 ℃ high temperature resistant adhesive for cooking bags was developed by the Institute of chemical industry. After several tests on the machine, its cooking resistance, content resistance, health and safety meet the requirements of domestic manufacturers.

复合折边袋包装食物后,要经121~135 ℃、30~40 min高温处理,所用包装资料一定是耐高温的。常用于蒸煮袋包装的资料有聚酯(PET)、尼龙(NY)、铝箔(Al)、流延聚丙烯(CPP)等。胶粘剂则是要用耐高温蒸煮的双组分聚氨酯胶粘剂。通过干式复合工艺制成复合膜。

After the food is packed in the composite folding bag, it should be sterilized at 121-135 ℃ for 30-40 min. the packaging data used must be heat-resistant. Materials commonly used in cooking bag packaging are polyester (PET), nylon (NY), aluminum foil (AL), cast polypropylene (CPP), etc. The adhesive is a two-component polyurethane adhesive with high temperature resistance. The composite film was made by dry composite process.

干式复合首要工艺过程是基材经网线辊涂胶后进烘道鼓风加热干燥与基材借复合钢辊加热加压后收卷制成复合膜。然后送到烘房加热熟化几天后,进行分切后制袋。

The primary technological process of dry lamination is that the substrate is heated and dried by blowing in the drying channel after being glued by the wire roller, and the composite film is made of the substrate after being heated and pressurized by the composite steel roller. Then it is sent to the drying room for heating and curing for a few days, and then the bag is made after cutting.

上一篇:影响自封袋收缩率的因素有哪些

下一篇:气泡袋主要有哪些重要的作用?

相关产品

-

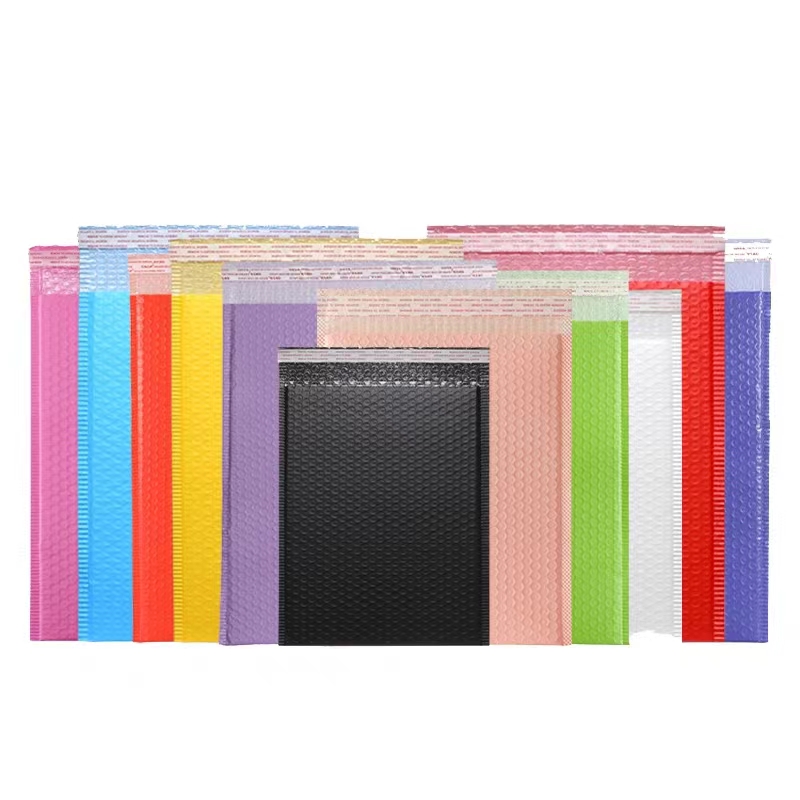

珠光膜气泡信封袋

-

气泡快递袋

-

服装拉链袋

-

防震快递袋

相关新闻

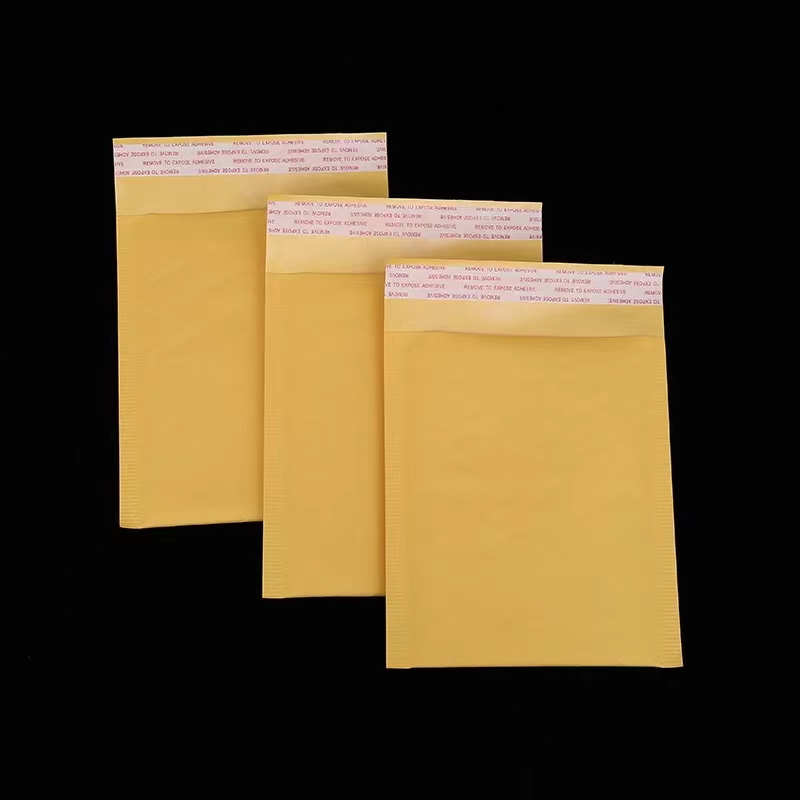

- 牛皮纸复合气泡袋知识

- 快递气泡包装袋为什么比较好用?

- 塑料包装发展趋势环保是!

- 正确使用抗静电塑料袋的方法

- OPP袋是什么材质的塑料袋?

- 拉链袋使用注意的地方

- 识别全生物降解垃圾袋知识

- 气泡袋的泡径和厚度对其质量的影响